Li-ion

Introduction

The alarming energy crisis and the shift in world climate is a clear indicator of the urgency of switching to cleaner energy sources at every level. As the future of energy storage solution, Lithium-ion battery technology, provides sustainable changes in transforming our way to store and consuming energy.

Lithium-ion batteries have been widely adopted in the production of electric vehicles. In the material handling market, Li-Ion batteries became popular mainly with entry level pallet trucks due to the introduction of the Easymove 12EZ from Easymove Equipment in 2020. Since then, entry level pallet trucks are mainly produced with Li-Ion batteries, though the technology used can differ quite significantly, leading to different characteristics and safety standards. Larger equipment has been available with Li-Ion options for several years already, but at the same time it was always extremely expensive and payed of mainly in heavy duty, 3 shift application. With the development of new trucks, this obstacle can be eliminated, and all categories of material handling products can be powered by Li-Ion technology in the near future, according to Easymove Equipment studies.

Zero maintenance

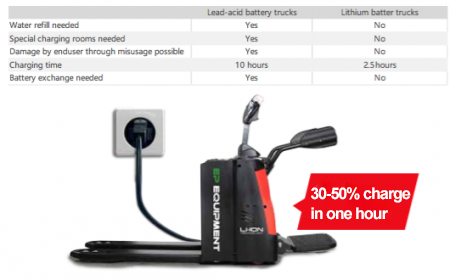

While lead-acid batteries need special maintenance, Lithium batteries don’t require active maintenance to extend their service life. That largely eliminates the costs of battery upkeeping, maintenance and infrastructure.

Less Expensive

It’s important to compare energy prices to ensure you’re getting a great deal for your Lead acid battery products and Li-ion ones.

In a nutshell, lead acid batteries may be less expensive from procurement perspectives, however, a lithium battery solution may contribute to a more cost-efficient warehouse operation in a long run:

- Less expense and energy spent on charging batteries

- No time and labour involved by swapping batteries

- Less time and labour spent maintaining and watering lead-acid batteries

- Reduced waste of energy (a lead-acid battery normally uses up to 50% of its energy through heat, while a lithium battery uses only up to 15%)

- Smaller overall battery size leads to similar purchase costs and offer the same or better autonomy due to opportunity charging.